|

Quality is the most essential for Rimemo. At the beginning of our establishment, we set the foundation of "survival by quality and development by innovation". |

|

|

First, strictly control the in coming raw materials. Rimemo selects qualified suppliers of raw materials, and ensures that the raw materials meet the environmental protection requirements of our target market. - The raw materials of MDF: meet European E1 and California CARB P2 standards. |

CARB P2 standards |

|

Material moisture test |

- The raw materials of PVC: to meet the test standard of REACH phthalate 7 P. Testing Company: ITS - The raw materials of wood: to have a testing of moisture, to ensure that the product does not produce mildew due to high humidity of raw materials. |

|

- The glue in production: to meet the requirements of Reach standard on inspection. Testing Company: SGS On the premise of ensuring that qualified suppliers provide raw materials, the department responsible for product testing will randomly inspect the commonly used raw materials every year, to ensure that the raw materials of each batch from suppliers meet the testing requirements. |

|

|

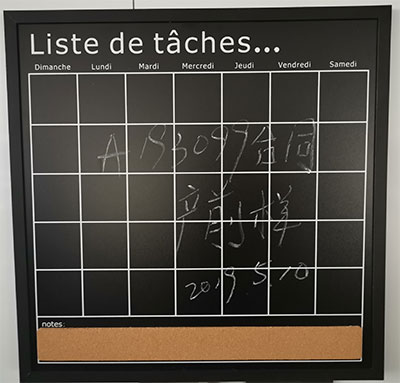

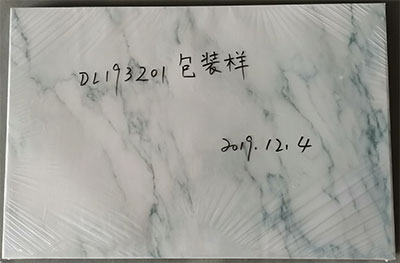

Secondly, Pre Production Sample to ensure all the details. After the raw materials arrive at the factory, in order to ensure the correctness of each order and product quality, the factory should make the pre-production samples of order products, which are placed in the prominent position of workshop after confirming with the client, to ensure that the workers check whether the products produced are conformity with the pre-production samples of the order before continuing production. The correct pre-production sample will provide security for inspection. |

|

From the beginning of the establishment, in line with the "quality first, client first" principle, we put product quality in the first position. Taking the philosophy that only excellent product quality can better serve the client's business as the criterion, our company has formulated a strict inspection process. In order to ensure the quality and correctness of the order products, the inspection department will inspect the order three times when the large goods production is 10%, 50%, 100%. Although the emphasis of these three inspections is different, they are all to ensure and improve the accuracy of the order products and the quality stability of the order products. |

|

|

Measuring the length

Measuring the width

Measuring the thickness |

- Inspection at 10% of production. When the order product is finished 10%, the first inspection is carried out to ensure the correctness of the product process, surface printing, function and so on. |

|

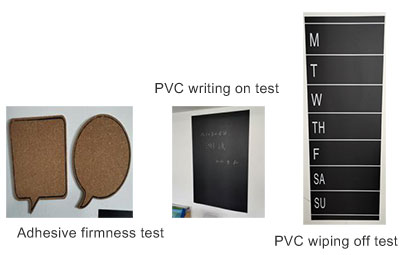

b. Test the function of the products, message board products test writing, wiping, hanging and printing firmness. |

|

|

c. Products with glue need to test the adhesion of common walls, writing test, wipe test, and so on. |

|

For example, for the flatness of products with border, whether the border angle is flat and the corner is exposed. For frameless products, whether the package corner is stuck firmly and the bubble bulge is on the product surface. For cork products, whether the coarse fineness of cork particles is consistent, and the density is in line with the requirements. For PVC products, whether the thickness is correct and the attached glue is firm. To find and solve the problems in time after the inspection in production, makes us solve the problems in the early stage of production, to work out product quality standards for workers and lay the foundation for later production. Inspection at 50% of production We will carry on a quality inspection when the production quantity is 50% of order. The inspection is mainly based on the product quality and is also more detailed than 10% inspection, such as whether the plate is shaking in the frame, whether there is glue leakage on the surface of the product, whether product printing is complete, whether the product back board, fiber board is in good condition, and whether there are cracks in the frame and so on. Ensure that the order product does not have these problems at 50% of production and then continue the production. |

|

|

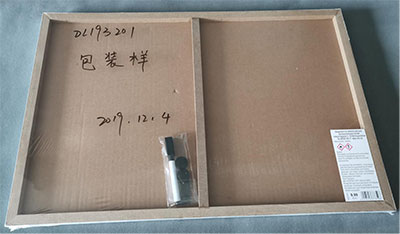

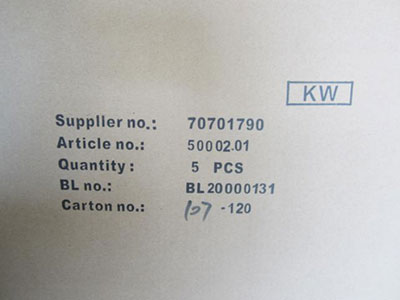

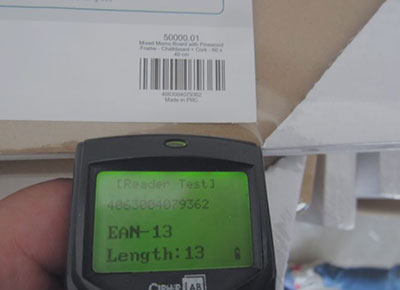

Inspection at 100% production and packaging. The final inspection will be in strict accordance with the international standard AQL4.0 to have a random inspection and take full set of mass production photos to save. Keep all the necessary information for the return order. a. Check whether the front and side mark printing on the outer box is correct, whether the barcode can be scanned, whether the outer box meets the export standards, and whether the outer box is with opening protection. |

|

|

b. Check whether the quantity of products in the outer box is consistent with the customer's requirements. |

|

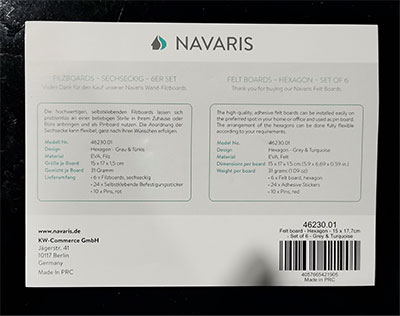

c. Check whether the package is complete and there is no damage |

|

|

d. Open the package and check the product labels, bar codes and accessories again to ensure the correctness of the whole set of products. |

|

e. Test its functions according to different products, such as memo board products are tested writing on and wiping off, and scratch-off products are tested whether the coating can be scratched off.

|

f. Have a quality inspection according to the order quantity and AQL sampling inspection quantity standard. |

|

According to AQL4.0 standard if any problem is found after inspection and the number of problems does not exceed the standard number, the problem product shall be replaced. If the number of problems is more than the standard quantity, the factory is strictly required to rework the order products. After the rework is completed, the factory shall carry out the second inspection. The inspection standard is exactly the same as the first inspection. Ensure the quality of each order by three inspections of 10%, 50% and 100%. It is under our high standards and strict requirements that the inspection pass rate of the production has been maintained at more than 98%, so as to reassure old clients and satisfy new ones. Most of our clients have established a good cooperative relationship with our company and continue to increase orders. Rimemo always put quality at the first position If innovation is our "ticket" to exploit the international market, the product quality is our "pass" in international market development. The quality is the core competitiveness. It is a prerequisite for companies to realize sustainable development. On the basis of enhancing innovation ability, it is the top priority of our Q.C.'s daily work to improve product quality. The QC department will carry out 10%, 50% and 100% inspection of each order all the time according to our inspection standards, so as to ensure the quality safety of each order, let the client rest assured, and make efforts to serve every client. |

|